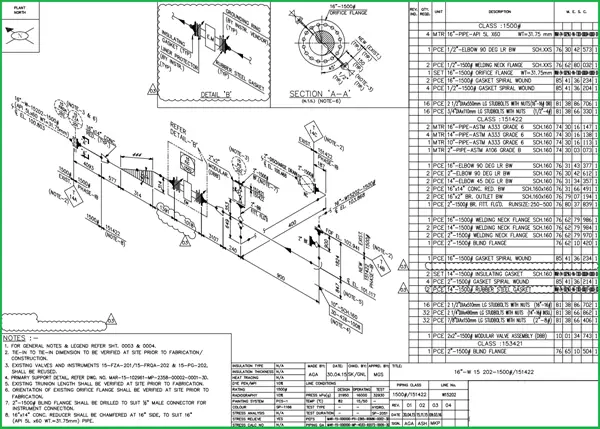

This piping is assembled in the shop and conveyed to the construction site for installation.Īll pipespools to be constructed by the fabricator are listed in the Pipespool Index. The word pipespool, as used in this specification, is a unit of prefabricated piping consisting of pipe, fittings, flanges, and other components integral to the assembly. PIPE SPOOL DEFINITION - Piping Fabrication and Erection Specification Inspection & Test of Piping ConstructionĪll piping will be fabricated by a field construction crew either in a pipespool fabrication shop hereinafter referred to as the "shop” (as per -) or in‑place hereinafter called the "field".Ģ.2. The following specifications are applied as supplement of this specification. RELATED ENGINEERING & CONSTRUCTION SPECIFICATION Wrought Stainless Steel Butt Welding Fittings MSS-SP-43īoiler and Pressure Vessel Code ASME-VIIIġ.3. W elded and seamless W rought Steel Pipe ASME B36.10 Square and Hex Nuts (Inch Series) ASME B18.2.2 Pipe Flange s and Flanged Fittings NPS 1/2” ASME B16.5įactory-Made Wrought Steel Butt w elding Fittings ASME B16.9įorged Steel Fittings, Socket Welding and Tread ed ASME B16.11

Pipe Threads, General Purpose (Inch) ASME B 1. SpecificationStandards referred to in this specification shall be the latest editions, including all revisions and addenda as listed below: CODES AND STANDARDS - Piping Fabrication and Erection Sound engineering practice shall be followed in the absence of specified standards or specification subject to OWNER prior approval.ġ.2. Where this specification and the petroleum refinery piping code ASME B31.3 conflict, this standard shall govern. Required by the applicable procedure and standards.ġ.1. both shop andįield fabrication include cutting, threading, bending, welding, bolting, etc.Ĭertificates, welding operations and execution, administration of allĭestructive & non-destructive examination and all testing operations as Of pipe supports including installation of spring supports, etc. Line mounted filters, ejectors sample cooler, etc. This specification covers the minimum basic requirements for various aspects of the above ground piping and in trench piping for the industrial plants as follow:Ī) Shop and filed fabrication and erection of piping.ī) Installation of in-line instrument items like orificeįlanges, control valves, rota meters, safety valves, etc.

This content provides you with a sample Piping Fabrication and Erection Specification that is useful for field inspectors. Piping Fabrication and Erection Specification

0 kommentar(er)

0 kommentar(er)